High Precision 316l Stainless Steel Tubing , SS Seamless Tubes

Polished Surface

TP316L, Chemical composition

| Element | Composition, % |

| Chromium | 16.0-18.0 |

| Nickel | 10.0-14.0 |

| Molybdenum | 2.0-3.0 |

| Manganese | 2.00 max. |

| Silicon | 1.00 max. |

| Carbon | 0.035 max. |

| Sulfur | 0.030 max. |

| Phosphorous | 0.045 max. |

Application: Standard oil and gas CRA (corrosion resistant alloy)

Tensile strength, min.: 70ksi (485MPa)

Yield strength, min.: 25ksi (170MPa)

Elongation in 2 in., min.: 35%

Application (seamless tubing)

TP316L seamless pressure tubing in the heat treated condition is

typically used in oil and natural gas wells for applications

including hydraulically-actuated surface-controlled subsurface

safety valves, chemical injection, and instrumentation. In such

applications, it is commonly referred to as control line tubing.

The tubing is generally deployed by strapping it to the outside of

the production casing. It may be encapsulated and can be included

along with other pressure or TEC and mechanical components, such as

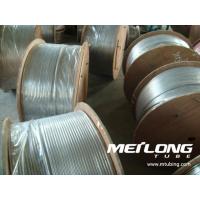

bumpers, within a flatpack. The tubing is frequently supplied as

5,000 to 35,000 ft. coils on a wooden or steel reel, depending on

size.

Description

TP316L is a chromium - nickel austenitic stainless steel with an

addition of molybdenum and reduced carbon content. The addition of

molybdenum provides improved resistance to pitting and crevice

corrosion in environments containing halides such as chlorides when

compared to so-called conventional 18 chromium 8 nickel austenitic

stainless steels such as 304L. The reduced carbon content minimizes

harmful chromium carbide precipitation during welding and thereby

improves resistance to intergranular corrosion. Austenitic

stainless steels such as 316L are susceptible to stress corrosion

cracking (SCC) in environments containing chlorides and other

halides. Alloy 316L is generally used in oil and gas production

environments which do not contain oxygen and have limited amounts

of chlorides and hydrogen sulfide. Consult ISO 15156-3, Table A.2

for the limits regarding alloy 316L in hydrogen sulfide containing

environments for oil and gas production.

HYDRAULIC AND INSTRUMENTATION APPLICATIONS

STAINLESS STEEL AND HIGH NICKEL ALLOYS COILED TUBING SOLUTIONS

MEILONG is an important manufacturer in premium coiled seamless &

welded tubular solutions for oil and gas applications. In an

endeavor to increase its presence in subsea, MEILONG has extended

its offer by developing a highly innovative tubular solution for

umbilical projects.

MEILONG has developed a strong and unique expertise in premium

quality tubes to answer the most stringent specifications of its

customers. Based on this expertise in high pressure, and extremely

high pressure tubes, MEILONG’s state-of-art factory is exclusively

dedicated to the manufacturing and supply of super duplex and high

nickel alloys tubes for corrosive downhole applications and is now

ready to offer the highest specifications for your toughest

challenges.

NDT

Full online and real time controls

100% of tube length & circumference Eddy Current & Ultrasonic

Testing

Inhouse Laboratory

Mechanical testing

Metallurgical testing

Dimensional controls

MEILONG has been supplying the world’s best coiled tubes up to

3,234 lbs (1,467 kgs) and 14,764 ft (4500 mtrs) length without

orbital butt welding.

Bright annealing treated, our coiled tubes are excellent in both

internal and external surface quality.

Our coiled tubes are specially used in oil and gas industry

requiring a higher level of reliability.

All the products are performed and delivered after ECT as well as

hydrostatic & ovality test satisfying ASTM standards.

| Materials | Imperial Size | Metric Size |

OD (in.) | WT (in.) | OD (mm) | WT (mm) |

SS316L Duplex 2205 Super Duplex 2506 Incoloy 825 Inconel 625 | 1/8 | 0.125 | 0.028 | 3.18 | 0.71 |

| 1/8 | 0.125 | 0.035 | 3.18 | 0.89 |

| 1/4 | 0.250 | 0.035 | 6.35 | 0.89 |

| 1/4 | 0.250 | 0.049 | 6.35 | 1.24 |

| 1/4 | 0.250 | 0.065 | 6.35 | 1.65 |

| 3/8 | 0.375 | 0.035 | 9.53 | 0.89 |

| 3/8 | 0.375 | 0.049 | 9.53 | 1.24 |

| 3/8 | 0.375 | 0.065 | 9.53 | 1.65 |

| 3/8 | 0.375 | 0.083 | 9.53 | 2.11 |

| 1/2 | 0.500 | 0.049 | 12.70 | 1.24 |

| 1/2 | 0.500 | 0.065 | 12.70 | 1.65 |

| 1/2 | 0.500 | 0.083 | 12.70 | 2.11 |

| 5/8 | 0.625 | 0.049 | 15.88 | 1.24 |

| 5/8 | 0.265 | 0.065 | 15.88 | 1.65 |

| 5/8 | 0.625 | 0.083 | 15.88 | 2.11 |

| 3/4 | 0.750 | 0.049 | 19.05 | 1.24 |

| 3/4 | 0.750 | 0.065 | 19.05 | 1.65 |

| 3/4 | 0.750 | 0.083 | 19.05 | 2.11 |

Applied Standard

ASTM A213: Standard specification for seamless and austenitic

alloy-steel boiler, superheater, and heat exchanger tubes

ASTM A262: Practices for detecting susceptibility to intergranular

attack in austenitic stainless steels

ASTM A269: Standard specification for seamless and welded,

austenitic stainless steel tubing for general use

ASTM A370: Test methods and definitions for mechanical testing of

steel products

ASTM A450: Standard specification for general requirements for

carbon, ferritic alloy, and austenitic alloy steel tubes

ASTM A632: Standard specification for seamless and welded,

austenitic stainless steel tubing (small diameter) for general use

NACE MR 0175: Selection and qualification of carbon and low-alloy

steels, corrosion-resistant alloys, and other alloys for service in

equipment in oil and natural gas production and NG treatment plants

in H2S-containing environment

EN10204: Inspection documents for metallic products

Manufacturing Process and Resultant Properties

Seamless extruded tube hollows are drawn or drawn / sunk to final

size to produce seamless tubing coils 500 to 2,000 ft. long,

depending upon the size. The tubing is heat treated and joined by

orbital welding to achieve the desired length. The final material

condition of the tubing is heat treated.

Nondestructive Testing (NDT)

Eddy current testing (ECT) is performed at final size in the heat

treated condition. Radiographic testing is performed on all orbital

welds. Yield pressure hydrostatic testing is performed on the heat

treated tubing at final size.

Quality Assurance

Eddy current test (ECT)

Ultrasonic test

Hydrostatic test

Chemical composition analysis

Tensile test

Hardness test

Dimension & visual inspect

Metallographic analysis

Standards and Specifications

ASTM A269, Standard Specification for Seamless and Welded

Austenitic Stainless Steel Tubing for General Service

Meets the material limits for 316L austenitic stainless steel

listed in ISO 15156-3, Table A.2.

Norm Equivalence

| Grade | UNS No | Euro norm | Japanese |

| No | Name | JIS |

| Alloy | ASTM/ASME | EN10216-5 | EN10216-5 | JIS G3463 |

| 316L | S31603 | 1.4404, 1.4435 | X2CrNiMo17-12-2 | SUS316LTB |

| 2205 | S31803 | 1.4462 | X2CrNiMoN22-5-3 | SUS329J3LTB |

| 2507 | S32750 | 1.4410 | X2CrNiMoN25-7-4 | |

| 625 | N06625 | 2.4856 | NiCr22Mo9Nb | |

| 825 | N08825 | 2.4858 | NiCr21Mo | |