Incoloy Alloy UNS N08825 Encapsulated Control Line Bright Annealed

Seamless

HYDRAULIC CONTROL LINE APPLICATIONS

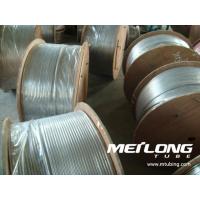

STAINLESS STEEL AND HIGH NICKEL ALLOYS COILED TUBING SOLUTIONS

MEILONG is an important manufacturer in premium coiled seamless &

welded tubular solutions for oil and gas applications. In an

endeavor to increase its presence in subsea, MEILONG has extended

its offer by developing a highly innovative tubular solution for

umbilical projects.

MEILONG has developed a strong and unique expertise in premium

quality tubes to answer the most stringent specifications of its

customers. Based on this expertise in high pressure, and extremely

high pressure tubes, MEILONG’s state-of-art factory is exclusively

dedicated to the manufacturing and supply of super duplex and high

nickel alloys tubes for corrosive downhole applications and is now

ready to offer the highest specifications for your toughest

challenges.

High quality polymeric jackets/encapsulations provide added

protection

Core tubing is evaporated with the latest thermoplastic elastomeric

compounds designed to outlast the life of most project tubing

installations by reducing the possibility of corrosion and

mechanical damage. They can stand up to a wide range of chemical

inhibitors and seawater. Most jackets are manufactured from fire

retardant, all-weather, abrasion-resistant compound, designed to

remain strong and flexible through wide ranges of temperatures and

pressures.

PVC

PP (polypropylene)

SP (Santoprene)

F46 (FEP)

Nylon

Incoloy Alloy N08825, Chemical composition

| Element | Composition, % |

| Chromium | 19.5-23.5 |

| Nickel | 38.0-46.0 |

| Ferrous | 22.0 min. |

| Molybdenum | 2.5-3.5 |

| Manganese | 1.00 max. |

| Silicon | 0.50 max. |

| Carbon | 0.050 max. |

| Sulfur | 0.030 max. |

| Aluminum | 0.20 max. |

| Titanium | 0.6-1.2 |

| Copper | 1.5-3.0 |

Application: Very good sour well and chloride stress corrosion

cracking resistance.

Tensile strength, min.: 85000psi (586MPa)

Yield strength, min.: 35000psi (240MPa)

Elongation in 2 in., min.: 30%

Application

Incoloy Alloy N08825 seam welded pressure tubing in the heat

treated condition is typically used in oil and natural gas wells

for chemical injection applications. In such applications, it is

commonly reffered to as capillary tubing and is free-hanging

(self-supporting) inside the production casing. The chemicals being

injected are often used to enhance production flow rates, inhibit

corrosion or scaling and/or de-water. The tubing is frequently

supplied as 5,000 to 35,000 ft. coils on a wooden reel, depending

on size.

Description

Incoloy Alloy N08825 is a titanium-stabilized austenitic

nickel-iron-chromium alloy with additions of molybdenum and copper.

The chemical composition of the alloy is listed in Table 1. The

alloy is characterized by good resistance to stress-corrosion

cracking due to its nickel content (38.0 to 46.0) and satisfactory

resistance to pitting and crevice corrosion. Incoloy Alloy N08825

has shown good corrosion resistance in oil and gas production

environments containing hydrogen sulfide, carbon dioxide and

chlorides. Consult ISO 15156-3, Table A.14 for the limits regarding

material type 4c in hydrogen sulfide containing environments for

oil and gas production.

Standards and Specifications

ASTM B704, Standard Specification for Welded UNS N06625, UNS

N06219, and UNS N08825 Alloy Tubes, except in the as-cold worked

condition

ASTM B423, Standard Specification for UNS N08825 Seamless Pipe and

Tube

Meets the material limits for annealed and cold-worked, solid

solution, nickel-based alloys listed in ISO 15156-3 for material

type 4c in Table A.14.

Production Process

Welded & Redrawn Tubing

Strip splice welds join lengths of cold rolled strip to enable long

lengths between orbital welds (greater than 14,500 ft between

orbital welds is achievable). The strip is formed into a tubular

cross section and longitudinally seam welded using the gas tungsten

arc (GTAW) process. The tubing is first sunk to an intermediate

outside diameter, heat treated, and make the same process to obtain

the desired size.

Seamless & Redrawn Tubing

Seamless extruded tube hollows are drawn or drawn / sunk to final

size to produce seamless tubing coils 500 to 2,000 ft. long,

depending upon the size. The tubing is heat treated and joined by

orbital welding to achieve the desired length. The final material

condition of the tubing is heat treated.

Quality Assurance

Eddy current test (ECT)

Ultrasonic test

Hydrostatic test

Chemical composition analysis

Tensile test

Hardness test

Dimension & visual inspect

Metallographic analysis

Coiled Encapsulated Tubing (Bare Tubing Size)

| Imperial size | Metric size |

OD inch | WT inch | OD mm | WT mm |

| 1/4 (0.250) | 0.035 | 6.35 | 0.89 |

| 0.049 | 6.35 | 1.24 |

| 0.065 | 6.35 | 1.65 |

| 0.083 | 6.35 | 2.11 |

| 3/8 (0.375) | 0.035 | 9.53 | 0.89 |

| 0.049 | 9.53 | 1.24 |

| 0.065 | 9.53 | 1.65 |

| 0.083 | 9.53 | 2.11 |

| 1/2 (0.500) | 0.035 | 12.7 | 0.89 |

| 0.049 | 12.7 | 1.24 |

| 0.065 | 12.7 | 1.65 |

| 0.083 | 12.7 | 2.11 |

| 5/8 (0.625) | 0.049 | 15.88 | 1.24 |

| 0.065 | 15.88 | 1.65 |

| 0.083 | 15.88 | 2.11 |

Tubing length up to 32,808 feet (10,000 m)

For control line, chemical injection line, umbilicals

Available materials

Austenitic: 316L

Duplex: S31803, S32205

Super Duplex: S32750

Nickel alloy: N06625, N08825

Norm Equivalence

| Grade | UNS No | Euro norm | Japanese |

| No | Name | JIS |

| Alloy | ASTM/ASME | EN10216-5 | EN10216-5 | JIS G3463 |

| 316L | S31603 | 1.4404, 1.4435 | X2CrNiMo17-12-2 | SUS316LTB |

| 2205 | S31803 | 1.4462 | X2CrNiMoN22-5-3 | SUS329J3LTB |

| 2507 | S32750 | 1.4410 | X2CrNiMoN25-7-4 | |

| 625 | N06625 | 2.4856 | NiCr22Mo9Nb | |

| 825 | N08825 | 2.4858 | NiCr21Mo | |