S31803 Super Duplex Stainless Steel Pipe , Annealed Stainless Steel

Tubing

Duplex Stainless S31803, Chemical composition

| Element | Composition, % |

| Chromium | 22.0-23.0 |

| Nickel | 4.5-6.5 |

| Molybdenum | 3.0-3.5 |

| Manganese | 2.00 max. |

| Silicon | 1.00 max. |

| Carbon | 0.030 max. |

| Sulfur | 0.020 max. |

| Phosphorous | 0.030 max. |

| Nitrogen | 0.14-0.20 |

Application: High mechanical strength and good resistance to

localized cracking & chloride stress corrosion.

Tensile strength, min.: 90ksi (620MPa)

Yield strength, min.: 65ksi (450MPa)

Elongation in 2 in., min.: 25%

Hardness, max.: Brinell 290, or Rockwell C 30.5

Standards and Specifications

Tubing Specification PTM-TS-011, Duplex Stainless S32205 Tubing for

Control Line Applications

ASTM A789, Standard Specification for Seamless and Welded

Ferritic/Austenitic Stainless Steel Tubing for General Service

Meets the material limits for duplex stainless steel with PREN 30

to 40 as listed in ISO 15156-3, Table A.24

Application

Duplex Stainless S31803 seamless pressure tubing in the heat

treated condition is typically used in oil and natural gas wells

for chemical injection applications. In such applications, it is

commonly referred to as capillary tubing and is free-hanging

(self-supporting) inside the production casing. The chemicals being

injected are often used to enhance production flow rates, inhibit

corrosion or scaling and/or de-water. However, the tubing can also

be used for control line tubing applications including

hydraulically actuated surface-controlled subsurface safety valves.

For control line applications, the tubing is generally deployed by

strapping it to the outside of the production casing. The tubing is

frequently supplied as 5,000 to 35,000 ft. coils on a wooden or

steel reel, depending on size.

A value offer for your umbilical tube challenges

The offshore industry is facing new challenges with tougher

operating conditions that are significantly impacting the

performance of the umbilical. Subsea umbilical systems for deep and

ultra-deep offshore projects are more and more demanding regarding

injection capacities, number of functionalities, power requirements

and increased tie-back lengths.

- MEILONG umbilical tubes have been designed to increase the

reliability and performances of your umbilical systems while

ensuring the safety, flexibility and cost-effectiveness of your

projects.

- Yours operations are safe and reliable at higher temperatures and

pressure levels, with superior benefits.

- MEILONG tubes for umbilicals open new perspectives and capabilities

for ultra-deep water projects.

Quality Assurance

Non Destructive Tests: Hydrostatic Eddy Current Surface Roughness Dimensional Analysis

| Destructive Tests: Yield Strength Tensile Strength Elongation Positive Material Identification (PMI) Grain Size Rockwell Hardness |

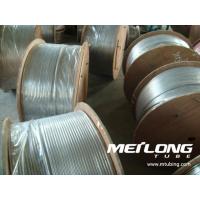

MEILONG has been supplying the world’s best coiled tubes up to

3,234 lbs (1,467 kgs) and 14,764 ft (4500 mtrs) length without

orbital butt welding.

Bright annealing treated, our coiled tubes are excellent in both

internal and external surface quality.

Our coiled tubes are specially used in oil and gas industry

requiring a higher level of reliability.

All the products are performed and delivered after ECT as well as

hydrostatic & ovality test satisfying ASTM standards.

Available size and alloy materials

| Materials | Imperial Size | Metric Size |

OD (in.) | WT (in.) | OD (mm) | WT (mm) |

SS316L Duplex 2205 Super Duplex 2507 Incoloy 825 Inconel 625 | 1/8 | 0.125 | 0.028 | 3.18 | 0.71 |

| 1/8 | 0.125 | 0.035 | 3.18 | 0.89 |

| 1/4 | 0.250 | 0.035 | 6.35 | 0.89 |

| 1/4 | 0.250 | 0.049 | 6.35 | 1.24 |

| 1/4 | 0.250 | 0.065 | 6.35 | 1.65 |

| 3/8 | 0.375 | 0.035 | 9.53 | 0.89 |

| 3/8 | 0.375 | 0.049 | 9.53 | 1.24 |

| 3/8 | 0.375 | 0.065 | 9.53 | 1.65 |

| 3/8 | 0.375 | 0.083 | 9.53 | 2.11 |

| 1/2 | 0.500 | 0.049 | 12.70 | 1.24 |

| 1/2 | 0.500 | 0.065 | 12.70 | 1.65 |

| 1/2 | 0.500 | 0.083 | 12.70 | 2.11 |

| 5/8 | 0.625 | 0.049 | 15.88 | 1.24 |

| 5/8 | 0.265 | 0.065 | 15.88 | 1.65 |

| 5/8 | 0.625 | 0.083 | 15.88 | 2.11 |

| 3/4 | 0.750 | 0.049 | 19.05 | 1.24 |

| 3/4 | 0.750 | 0.065 | 19.05 | 1.65 |

| 3/4 | 0.750 | 0.083 | 19.05 | 2.11 |

Duplex Stainless S31803, Characteristics and properties

Nominal Outside Diameter in. | Nominal Wall Thickness in. | Minimum Burst Pressure psi | Minimum Collapse Pressure psi |

| Min. | Min. | Min. | Min. |

| 0.250 | 0.035 | 27,391 | 17,441 |

| 0.250 | 0.049 | 38,348 | 23,028 |

| 0.250 | 0.065 | 50,870 | 28,442 |

| 0.375 | 0.035 | 18,333 | 12,222 |

| 0.375 | 0.049 | 25,667 | 16,489 |

| 0.375 | 0.065 | 34,048 | 20,930 |

| 0.375 | 0.083 | 43,476 | 25,371 |

| 0.500 | 0.035 | 13,777 | 8,091 |

| 0.500 | 0.049 | 19,288 | 12,798 |

| 0.500 | 0.065 | 25,586 | 16,444 |

| 0.500 | 0.083 | 32,672 | 20,233 |

| 0.625 | 0.035 | 11,035 | 4,990 |

| 0.625 | 0.049 | 15,449 | 9,903 |

| 0.625 | 0.065 | 20,494 | 13,478 |

| 0.625 | 0.083 | 26,169 | 16,722 |

Description

Duplex Stainless S31803 is a duplex stainless steel. When properly

heat treated, the microstructure consists of a nearly equal mixture

of the austenitic and ferrite phases. This two-phase microstructure

produces a fine grain size which increases the yield strength. In

the final heat treated condition, Duplex Stainless S32205 can

achieve a yield strength approximately twice that of austenitic

alloys such as 316L, 825 and 625 which must be cold worked to

achieve comparable yield strengths. Duplex stainless steels are

often classified as lean, conventional, super or hyper based upon

their pitting resistance equivalent (PRE or PREN). Various PRE

formulas are used to rank an alloy’s resistance to chloride pitting

corrosion based upon its composition. Duplex Stainless S32205

typically has a PRE of 36 and is considered a conventional duplex

stainless steel. Duplex Stainless S32205 is often selected for use

in oil and gas production environments based upon its higher

strength and resistance to pitting, crevice and stress corrosion

cracking in chloride containing environments. Consult ISO 15156-3,

Table A.24 for the limits regarding the use of Duplex Stainless

S32205 in hydrogen sulfide containing environments for oil and gas

production.

Manufacturing Process and Resultant Properties

Welded & Redrawn Tubing

Strip splice welds join lengths of cold rolled strip to enable long

lengths between orbital welds (greater than 14,500 ft between

orbital welds is achievable). The strip is formed into a tubular

cross section and longitudinally seam welded using the gas tungsten

arc (GTAW) process. The tubing is first sunk to an intermediate

outside diameter, heat treated, and make the same process to obtain

the desired size.

Seamless & Redrawn Tubing

Seamless extruded tube hollows are drawn or drawn / sunk to final

size to produce seamless tubing coils 500 to 2,000 ft. long,

depending upon the size. The tubing is heat treated and joined by

orbital welding to achieve the desired length. The final material

condition of the tubing is heat treated.

Nondestructive Testing (NDT)

Eddy current testing (ECT) is performed on the longitudinally seam

welded tubing and strip splice welds in the as-heat treated

condition. Those strip splice welds detected by ECT. Yield pressure

hydrostatic testing is performed on the heat treated tubing at

final size.

Application

Oil and Gas: Subsea

Sub-Surface Safety Valves (SSSV) / Umbilicals: Tubes filled with

Hydraulic Fluid which run from floating platform or FPSO to the

well head on the sea floor.

Oil and Gas: Downhole

Downhole Control Lines: Tubes running from above ground surface

controls into a downhole well to the location of the well’s safety

valve.

Geothermal

Calcite Inhibition System: Carries chemicals into earth’s crust to

flash point of water in a geothermal well; injected to break down

calcite deposits and extend life of the well.

Instrumentation

Common connection tubing for control panels, pneumatic equipment,

and fluid lines.

Norm Equivalence

| Grade | UNS No | Euro norm | Japanese |

| No | Name | JIS |

| Alloy | ASTM/ASME | EN10216-5 | EN10216-5 | JIS G3463 |

| 316L | S31603 | 1.4404, 1.4435 | X2CrNiMo17-12-2 | SUS316LTB |

| 2205 | S31803 | 1.4462 | X2CrNiMoN22-5-3 | SUS329J3LTB |

| 2507 | S32750 | 1.4410 | X2CrNiMoN25-7-4 | |

| 625 | N06625 | 2.4856 | NiCr22Mo9Nb | |

| 825 | N08825 | 2.4858 | NiCr21Mo | |

Since 1999, Meilong Tube Co., Ltd. has produced long coils of

stainless steel and high nickel alloy tubing for numerous oil and

gas applications, including hydraulic power, monitoring and control

equipment, instrumentation, injection lines, down-hole safety valve

control, subsea umbilical applications. Unique manufacturing

capabilities and processes allow Meilong to produce the longest

continuous length control line tubing available in stainless steels

and high nickel alloys.

Our coiled tubing is available in a number of high performance

corrosion resistant stainless steels and high nickel alloys,

including 300 series, Incoloy, Inconel, capable of withstanding a

variety of severe environmental conditions.

We specialize in manufacturing small diameter tubing ranging from

0.125 inch to 1 inch outside diameter (3.18mm to 25.4 mm) and a

variety of wall thickness. All tubing is level wound coiled on

various size spools, and products are tested and evaluated for

specific applications before delivery. Our engineering staff

welcome the opportunity to work with customers to solve special

problems.

Meilong’s seamless control line tubing is drawn from seamless

extruded tube hollows to ensure absolute product safety and

reliability. Our seamless line tubing is one continuous length of

tubing, completely free of any welded joints or seams. Long length

coils reduce installation time and costs by eliminating the need

for excessive joints preparation and fittings. Elimination of

excessive fittings increase reliability and assures a leak-free

system. We are capable of 100% hydrotesting each coil.

In meeting customer’s requirements, our tubing can be encapsulated

in various materials such as thermalplastics, nylon and PVDF.

Coiled seamless control line tubing offers many advantages to

installers of hydraulic or pneumatic lines on offshore platforms

and onshore refineries. It offers unmatched safety and reliability,

while at the same time reducing the frequency of costly joint

connections. Close tolerance control during manufacturing assures

easy insertion and connection to fittings due to tubing’s inherent

ductility.

Downhole hole & umbilical tubing

Our long length seamless coils are used extensively for chemical

injection and hydraulic control in subsea and onshore wells. The

long length minimizes the number of orbital welds which reduces the

potential for weld-related defects and failures. Additionally, our

coils have an extremely clean and smooth ID surface that is ideal

for hydraulic and chemical injection systems. Seamless stainless

steel coils offer short hydraulic response time, greater collapse

strength, and elimination of methanol permeation.

Vacuum annealing

Meilong takes special care during manufacturing to assure ID and OD

cleanliness of control line tubing. Vacuum annealing insures

volatility of metallic oxides and removal of any residual

degreasing solvents or drawing lubricants. Vacuum annealing our

stainless steel tubing insures a bright, cosmetically appealing

surface as well as excellent mechanical properties.

Meilong commitment to quality excellence

From the time an order is received, sent through the production

process, completed, and finally shipped, many levels of inspection

occur to reinforce Meilong’s Quality Policy. The job of ensuring

quality products extends as far as our machine operators. Meilong

operators take ownership over material processed at their stations

by measuring for dimensional accuracy and conducting a visual

inspection of every piece.